EXCELLENT ACHIEVEMENTS

The consistent control of any production steps ensures best results and distinguishes our work as 0 ppm supplier.

TOP QUALITY MANAGEMENT

Quality is our benchmark that runs through all our divisions. Good qualification as well as continuing training and team work with significant synergistic benefits ensure highest manufacture and product quality. This is evidenced by our IATF 16949 certificate. We also operate according to the DIN EN ISO 14001 guidelines. Offering you the greatest possible benefit is our continuous endeavor – and our customers confirm that we are on the right track.

CONTROL OF ANY PRODUCTION STEPS

Our qualified employees constantly monitor the product quality at all production stages. For this purpose, we perform incoming goods-, production- and outgoing goods inspections and provide documentation in our Quality CAQ-System. Of course you will receive the test report upon request. Initial sampling is made according to standard procedures (VDA, PPAP).

Our Quality Management promotes our process of continuous improvement (CIP). We also consider your suggestions for continuous improvement as an opportunity.

OUR PRINCIPLES

Our corporate principles and their explanations are bindingly defined in our company’s credo. These principles are our mission statement. They comprise our long-term objectives, our field of activity aimed with RESPONSIBILITY, and our code of behaviour for all our functional areas. The Sustainable Balanced Scorecard (SBS) specifies our long-term objectives. Unlike the classic Balanced Scorecard (BSC), the SBS comprises among the determined economic objectives also ecological and social objectives. By acting in this way, we ensure avoidance of a one-sided goal pursuit and a balanced consideration of our sustainable objectives.

FACTS

- Our certificates: ISO 14001, IATF 16949

-

Use of reliable quality methods:

e.g. FMEA, CIP, Run&Rate, Balanced Scorecard

- 0 ppm supplier due to camera-based final inspection

HIGHEST PRODUCTION QUALITY

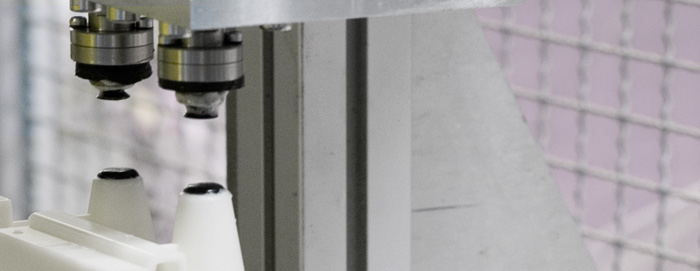

OPTICAL TESTING EQUIPMENT

For the inspection of safety-relevant precision parts, we have a fully automatic image processing test system at our disposal. Within a fraction of a second, the parts are optically recorded by our camera and laser systems. The digital images created go through electronical processings, and the inspection results are precised on the basis of optical and dimensional criteria. This is how we combine highest precision and top quality at low costs.

AUTOMATION

Our part-specific peripherals provide removal from the mould, parts‘ separation, mounting to assembly and complilation to packaging units. Another step towards automation is our optical testing equipment. As a 0 ppm supplier, we assure 100% control of the entire delivery.

SAMPLING

According to customers‘ requirements, we manufacture prototype moulds for which we have always reserved resources in toolmaking. This capability ensures high quality, perfect interaction with other assembly parts and flexibility at low cost.

WIDE RANGE OF SERVICES

We are experts for moulded parts made from thermoplastic, elastomer and liquid silicone. But why are we your ideal partner? Because of our six decades experience in manufacturing as well as in various industries! Share your idea with us: From component design through production of initial prototypes to reliable serial delivery. What’s your adavantage with us?

Lower costs and full focus on your business.

■ Top quality

■ High delivery reliability

■ Competitive prices

CONSTRUCTION

OUR EXPERIENCE IS BASIS FOR ANY NEW PROJECT

With more than 65 years of experience in the production of moulded parts, we provide the essential basis for top and reliable serial production. Because no matter technology, however, experience remains the key component in design.

PROTOTYPES

YOU ARE WELCOME TO BE CURIOUS!

Due to smart designs and the use of master forms, we are able to produce prototypes at low costs within a short time. First parts are thus already available during the development period.

LOGISTICS

AT YOUR DISPOSAL – WHENEVER YOU NEED IT

Just-in-time, safety stock, consignment stock, barcode system and customized packaging concepts –

A lot of our performance features ensure that your products reach the right place at the right time.

Reliably. One delivery after the other. From the very beginning.

PRODUCTION

QUALITY FIRST, OF COURSE

All our production facilities are connected to a central master computer system in order to achieve maximum transparency and continuous quality control in manufacturing processes. Our integrated tool maintenance additionally supports a smooth flow in process. All of this results in even greater efficiency throughout production.

ASSEMBLY

EVEN MORE THAN JUST INJECTION MOULDING

Assembling, marking, painting, stamping, combining into assemblies: by offering individual solutions we create the prerequisite for the integration of all subsequent work processes. Whether fully automatic or manual, but definitely customized to your requirements.

TESTING

0 DEFECTS = 100 % SATISFACTION

Upon request phase already, we provide a basis for reliable production and testing as the entire following production process is customized to your project. Our ambition: 0 ppm and supplying most satisfied customers worldwide.